The maintenance division of Geschke Pty Ltd, under guidance of Thomas Smole, continues to grow and enhance it’s reputation for quality and on time service across the industry.

HYDRAULIC SERVICES PREVENTATIVE MAINTENANCE

DETAILS OF TYPICAL SERVICES OFFERED

COMPANY INTRODUCTION

Geschke Plumbing Contractors is an established commercial plumbing business operating successfully in Melbourne since 1951. We are a family owned business that prides ourselves on quality installations and personal attention to detail. We deliver technical projects on time and defect free to all our clients.

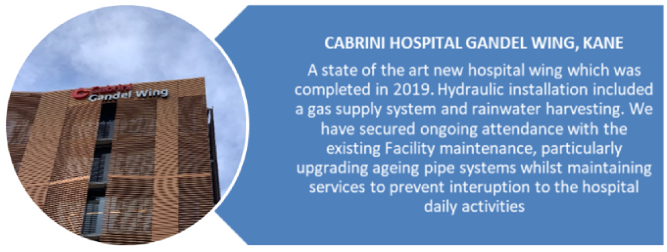

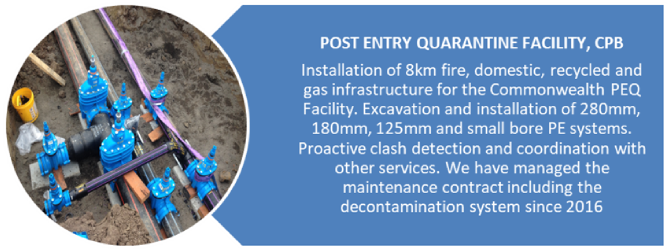

Our experience ranges from construction of new facilities such as Cabrini Hospital Gandel Wing and Werribee Mercy Hospital and high-rise apartment buildings. We are also involved in hydraulic system upgrades for universities and prisons as well as ongoing maintenance contracts for a range of applications including maintenance works at Royal Children’s Hospital and Monash Medical Centre. We are also a Honeywell and Spotless approved maintenance contractor.

The success of our company is our Team. We have a diverse range of people in our Head Office with a range of skills and qualifications and passion to match the size of the construction projects we are involved in. Our workforce is no exception, all our plumbers take great pride in their work and maintain a high level of quality for all projects.

We have plumbers readily available to undertake any level of plumbing. Preventative maintenance is detailed here and in the maintenance schedule, but should larger jobs be required we can mobilise quickly to undertake excavations or any type of works that might need attention

PROJECTS AND CONTRACTS

TYPICAL PREVENTATIVE MAINTENANCE

Maintaining the operation of all hydraulic systems

6 monthly service of pump systems including emergency sump pumps. This will include a service report upon each visit.

Maintenance for Sump Pumps Package –Sewer & Storm Pump Packages, Under-sink Pump Package:

Remove Pumps & Check the general Conditions of Pumps.

Check the condition of Submersible Motor & Cable.

Check winding Insulation Resistance of motors

Check condition of Impeller; Grinder Assembly (where fitted), Fastener conditions & other wear parts

Check Mechanical Seal/s operation is true & correct.

Check condition of Pump pedestals / Guide Rails / Lifting Chains

Check Level sensor condition & Operation

Check Controller Operation Function Testing; Sequence of Operation; Check Indicators; level Settings;

Check FL Amp Rating settings & compare with each pump operational Amp rating.

Check overall condition of the pumps station.

Check condition of Gatic Cover. Grease the gaps as necessary.

Check condition of Pipe work / Valves & Fittings in the pit. Check & Report if Individual Pump Ball Check Valves have been used.

Provide On-site Service Report

Provide Defects Report, If Any.

All work above shall be completed as per current OH&S requirements.

6 monthly service of domestic cold pump systems and hot water systems.

This will include a service report upon each visit.

Maintenance Procedure of Cold-Water Constant Pressure Pumps Packages:

Check the general Conditions of the Pumps / Motor & Complete Package

Check For undue Noise / Vibration in Pump & Motor Bearings

Check seal condition

Check Operation of Screen Filters

Check Operation of Controller

Controller Function Testing; Sequence of Operation; Check Indicators; Check Insulation Resistance; Check Amp Rating.

Provide On-site Service Report

Provide Defects Report, If Any.

Maintenance Procedure of Hot Water Systems:

Check Operation of Water Heater

Check Operation of Pump

Check Gas Pressure at water heater

Check and clean strainers

Check & Confirm Operation of Expansion Control Valve

Check and Confirm Operation of Inlet & Outlet Temperature Sensors

Check and Confirm Operation of Pressure Sensor

Controller Function Testing; Check Indicators; Check Insulation Resistance; Check Amp Rating.

Check faults log and report any critical errors

Provide On-site Service Report

Provide Defects Report, If Any.

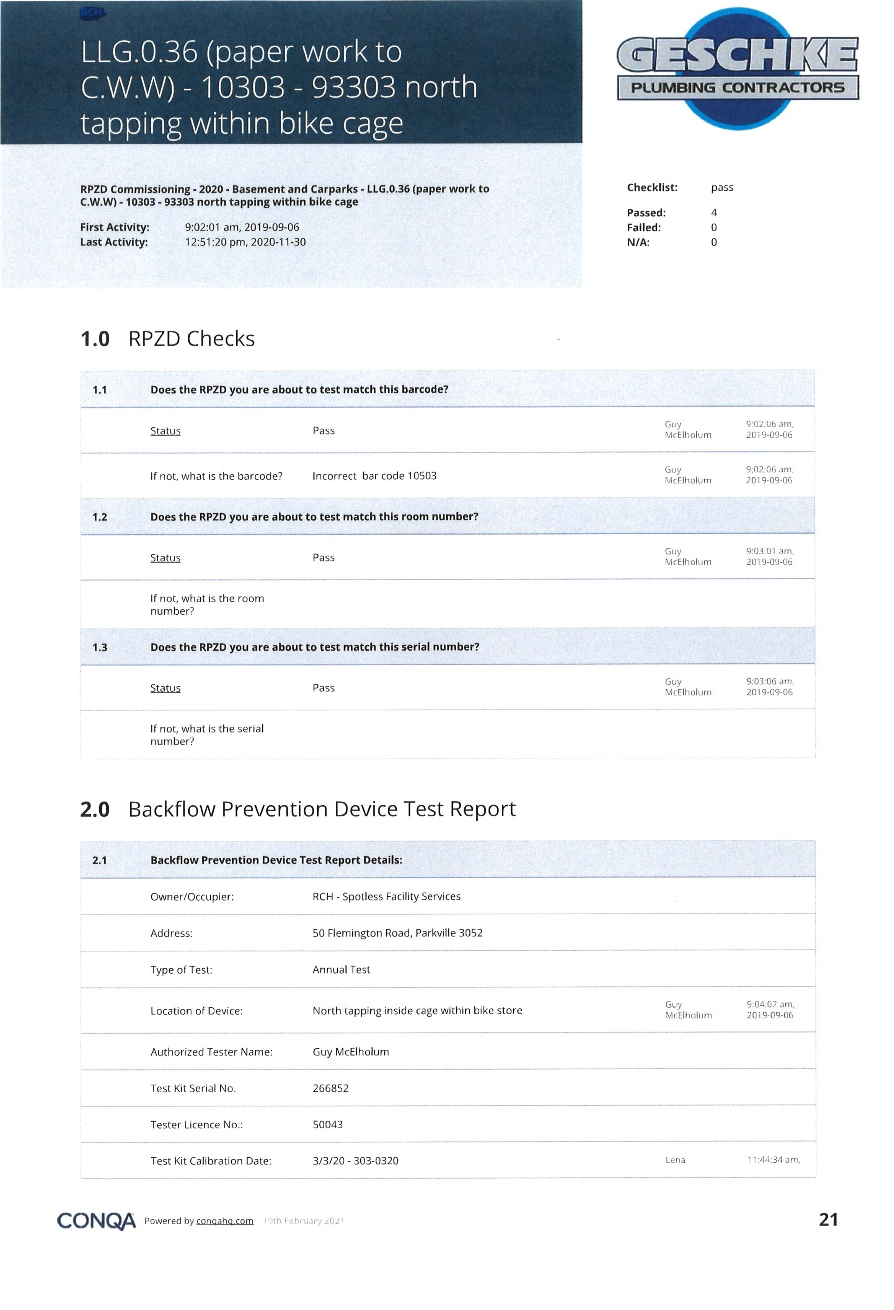

Annual hydraulic preventative maintenance

- Annual testing of Thermostatic mixing Valves (TMVs) including thermal flushing of temp line from TMV to each fixture. Spare parts are additional.

- Annual testing of Backflow Prevention Devices

- Eye Wash Safety Showers Flow Testing

- Annual inspection of sewer systems including all manholes and inspection openings. Additional costs for vacuum truck as required.

- Annual inspection of stormwater system including stormwater pits and downpipes. Additional costs for vacuum truck as required.

- General inspection of hydraulic pipework, including checks for leaks or corrosion

- Hot Water Units Operational Check

- Maintenance of Boiling Water Units and inspection and replacement for filters as required.

- Operational check of fixtures, appliances and equipment.

- Services including operational check of isolation valves and balance valve. Material replacements additional cost.

- Inspection of drain filter baskets and buckets traps (where applicable).

- Operational inspection of chemical dosing pumps and contracted top up of supplies.

Our capacity for Maintenance includes the following items:

- Emergencies – burst pipes, system fault requiring immediate rectification

- Repairs or replacements for fixtures

- Vacuum trucks for drain blockages

- Consumables

SYSTEM UPGRADES AND REPLACEMENT

Geschke Plumbing have been involved with major Hydraulic system replacements and upgrades in hospitals, laboratories, retirement villages, Office towers, infrastructure sites, Public Buildings, Railway facilities, Defence facilities, Naval bases, Ports, Residential accommodation and Universities.

These systems include:

Hot Water flow and return,

Domestic Cold water,

Reclaimed water,

Fire mains – hydrant and sprinkler

Gas mains

Sewer systems,

Stormwater pipework,

Reverse Osmosis plant and pipelines,

Trade waste systems

After hours and weekend works are usually required for these replacement contracts.

Final removal of the redundant systems and upgrading and replacing building fire rating systems form part of these works.

Our team meets with the facility management and occupants as required and, before work starts and develop agreed programs and plans of the staged activities.

We issue and get signed off by all associated parties forms for isolation and hot works etc.

We pride ourselves in the selection of quality materials for system replacements

Larger size water systems from 32mm to 300mm we typically use 5% silver soldered copper pipework.

On pipe systems 25mm 20mm and 15mm we use the Rehau sleeve system.

Inground mains are typically HDPE.

QUALITY ASSURANCE, AUTHORITY COMPLIANCE AND TEST REPORTING

Geschke Plumbing provide to the client test reports of all maintenance and replacement activities during the works and when completed.

We use internal QA procedures including mandatory authority testing reports and forms and upload and issue through our company web based “CONQA” reporting system including photos, plans, locations, pressure test reports, material conformance and Fire prevention conformance.

These are then transmitted to the client for their future reference.

Items that require authority documentation including Thermostatic mixing valves and backflow prevention devices are tested and documented by our licenced plumbers accredited in testing these devices.

CALL OUTS AND REPORTING

TO: Thomas Smole, tom@geschkegroup.net

CC: David Geschke, david@geschkegroup.net(For emergency response) Emergency Contacts:

1st response plumber options:

1. Thomas Smole, tom@geschkegroup.net, 0490 470 271

Geschke will facilitate equipment and fixture suppliers to attend site as required. Works may be required due to faulty equipment or general preventative maintenance.

Geschke will charge hours as per the call out rates detailed plus cost incurred from suppliers.

Geschke will also assess if works are covered under the warranty certification of the suppliers good, in which case no supplier costs will be incurred.

Included in our works is can be an annual visual inspection to confirm the fixtures are in working order..

These works include but are not limited to the following items:

• Fixtures

• Storage Tanks

• Vacuum Trucks

• Settlement Tanks

• Grease Interceptor Traps

• Consumables

Normal Time:

Normal time is 7am – 3.30pm.

Geschke call out inc. first 30 mins: $250 plus GST

Geschke hour rate thereafter: $170 / hour plus GST

After Hours:

Geschke call out inc. first 30 mins: $290 plus GST

Geschke our rate thereafter: $240 / hour plus GSTReporting -If requested by Client

A quality maintenance report will be kept up to date collating all items requiring maintenance and the dates they are scheduled and completed. Quality assurance inspection reports will also be kept along with necessary compliance reports. Items requiring additional works will be detailed within the folder with details of the works undertaken and any other applicable information. These reports will be kept in electronic format using the software system Conqa with service reports available upon request.